Technology

“Every advanced technology is barely different from magic”.

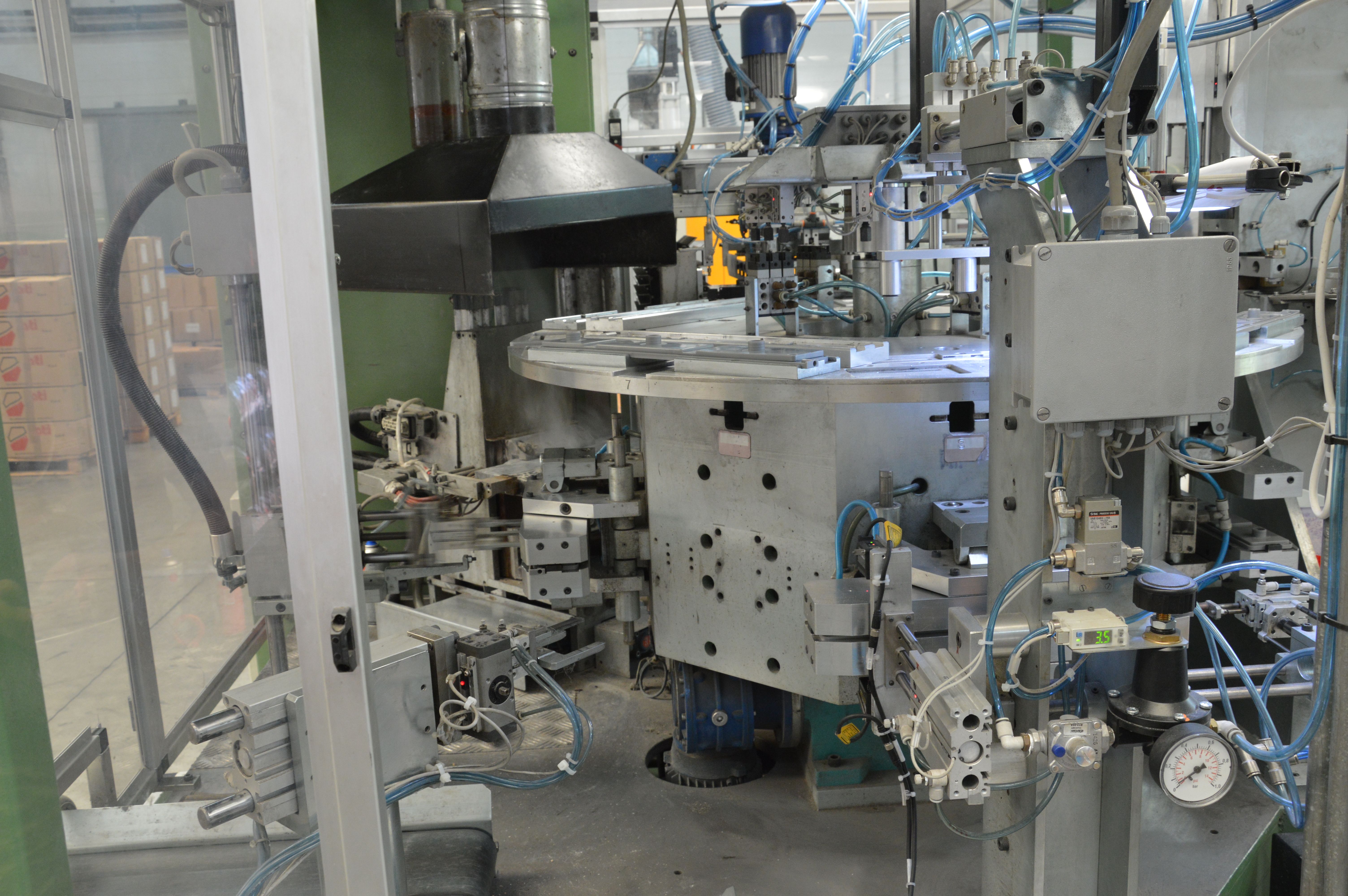

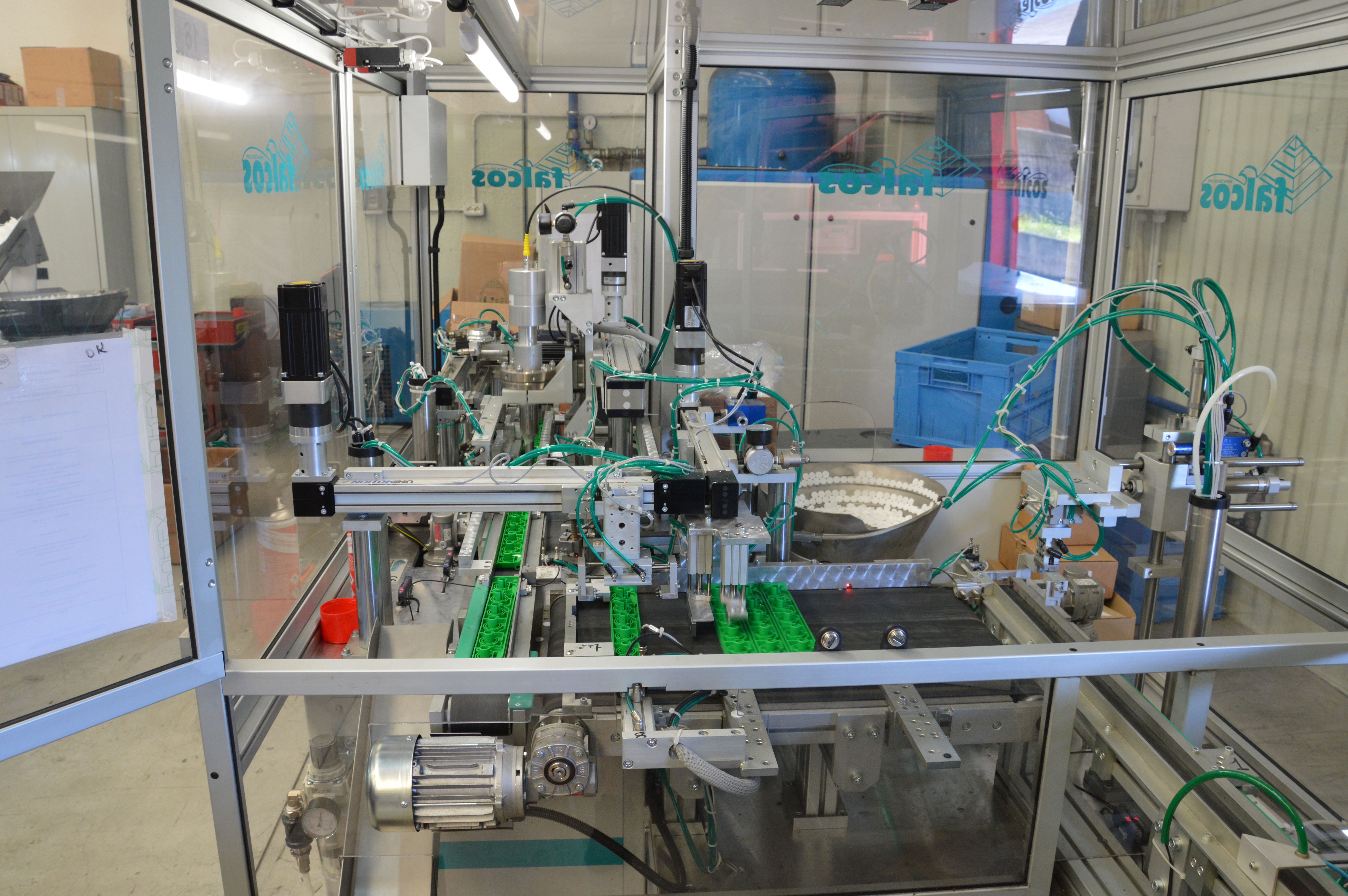

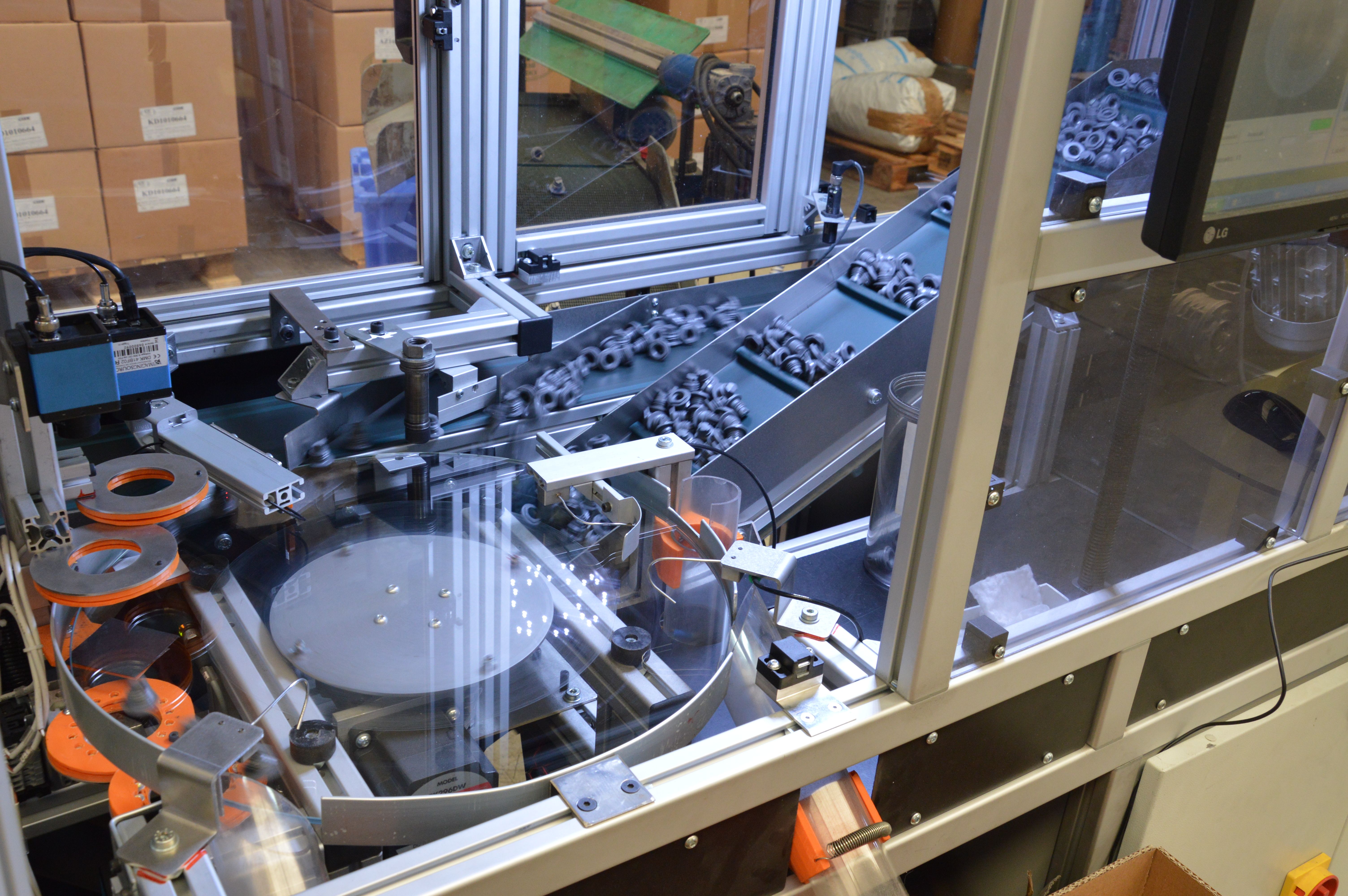

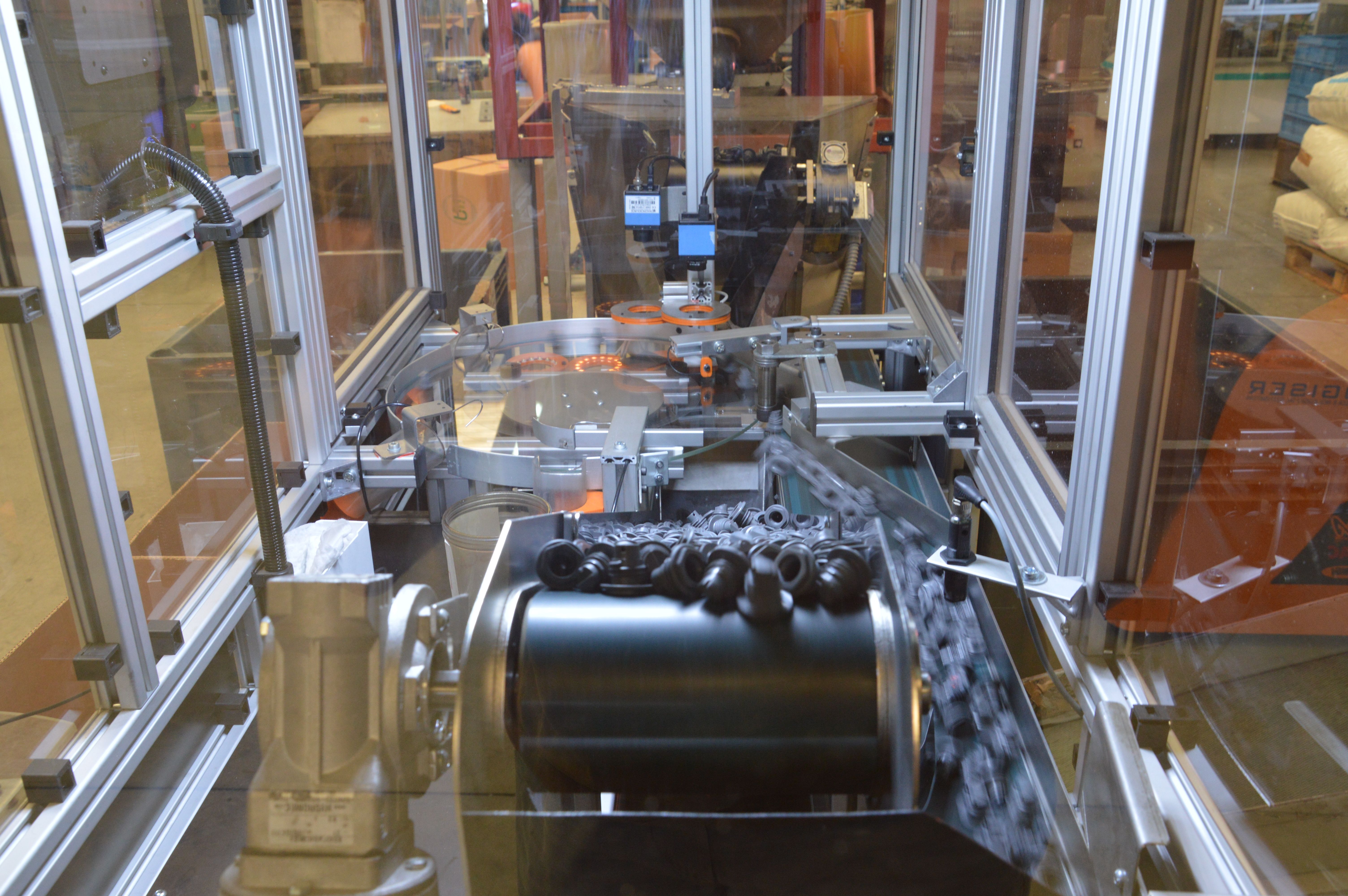

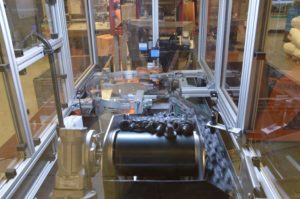

Our technology is divided into plastic moulding and assembling plastic components. We have the most modern injection moulding presses and we are increasing their number everyday. Most of our presses work 24/7. After being moulded, the components are sent to the assembling department, where they will be assembled and 100% controlled, so that the final customer can receive the finished product, where all the quality checks have already been made. In the assembling department, our automatic machines and welders are absolutely forefront: you can see them working in the video in this page.

Furthermore, we also work with the nearby best artisans for building and improving our moulds, together with an internal garage for moulds control and ordinary maintenance.

Regarding the quality certificates, we are certified ISO 9001:2015, available below. We assure 100% quality control on each moulded batch, by following the analysis and control methods which were established with the customer in order to maintain the best quality standards. Some of these quality controls are shown in the already mentioned video: for example, we perform specific view controls using high quality cameras and software to recognize the produced images and analyze the item dimensions, or air flows controls if an item has a vent-hole, etc. In short, each of our process is under rigorous control.

From 2023, we receive each year the “PRS Green Label” certificate, issued by PRS, a Dutch company that has been organizing the controlled reuse and shared use of pallets for over 20 years. PRS has created the “PRS Green Label” in recognition of the efforts of all active partners in the network of producers, processors, distributors, suppliers, warehouses who actively contribute to a better environment by returning the pallets used in their production to the Dutch company that collects them, repairs them if necessary, and then supplies them to the next customer.

Also, we perform rubber overmoulding and plastic inserts.

- 3x “NPM” FROM 30 TO 280 TONN. PRESSES

- 16x “RIPRESS” FROM 60 TO 260 TONN. PRESSES

- 6x “NEGRI BOSSI” FROM 80 TO 350 TONN. PRESSES

- 1x “FANUC” OF 100 TONN. PRESS

SOME OF THIS PRESSES ARE HYDRAULIC, SOME ELECTRIC AND THE OTHERS HYBRID.

The molds we use can be divided into our molds and customer’s molds.

In fact, we also work for work account: if you have your own mold but you cannot use it, go in the CONTACTS section of this website and write us: we can work together! If you have an idea or a project you would like to develop, contact us: we can make it grow together!

In more than 30 years of experience we learnt to deal with these plastic types:

- PP

- ABS

- PE/PET/PETG

- PMMA

- PBT

- PA

- PC

- BLEND

- PPS

- PVC

- SAN

- PSU